How is Chocolate Made?

FROM BEANS TO BAR

OVERVIEW

The seeds of the cacao tree have a bitter taste and must first be fermented to develop flavor. After fermentation the beans are dried, cleaned and then roasted. The shell of the cacoa bean is removed to produce cacao nibs. The nibs are then ground to produce cocao mass or pure chocolate in a rough form. This cocoa mass is usually in a liquid form (chocolate liquor) and is usually mixed with other components to form commercial chocolate. The liquor may also be processed in it's two components, cocoa solids and cocoa butter.

THE CACAO TREE

Chocolate comes from the cacao tree, which is formally known as Theobroma Cacao.The cacao tree is very delicate and sensitive needing protection from wind and requires shade especially during it's early years. Some strains are able to yield fruit after 3 or four years.

The trees yield four main varieties: or four

Criollo: Called the prince of cacaos, Criollo is a rare bean grown mainly in Central America and the Caribbean. Its pod is soft and thin and light-colored. Criollo is very high quality cacao beans and is mainly cultivated in South and Central America. The yield is fairly low.

Forastero: More commonly found and more productive, Forastero trees have thicker pods and a strong chocolate taste. Most cocoa is of this variety, and it thrives in Brazil and Africa.

Trinitario: This cross of Criollo and Forastero, which originated in Trinidad, is easily cultivated. It has smooth pods and flavorful beans.

The Nacional is mostly cultivated in South America west of the Andes. It is prone to disease and difficult to grow, but has an excellent aroma.

HARVESTING

At its maturity, the cultivated tree measures from 15 to 25 feet tall, though the tree in its wild state may reach 60 feet or more. The fruit of the cacao tree is a football-shaped pod. Picking ripe cacao pods is a difficult job. The cacao tree is frail and its roots are shallow making injury to workmen a risk cannot risk when trying to gain access to pods higher in the tree. After pods are removed from the tree they are collected in baskets and transported for the breaking operation. One or two length-wise blows from a well-wielded machete are usually enough to split open the woody shells. Farmers who are more careful will quickly rap the cocoa pod on a rock or tree, and the pod will quickly and easily break open, allowing the beans to be scooped out without damage. A good breaker can open 500 pods an hour. Anywhere from 20 to 50 cream-colored beans are scooped from a typical pod and the husk and inner membrane are discarded. Each cacao tree can produce between two and three pounds of dried cacao beans per year. Approximately 500 cacao beans will produce a pound of bittersweet chocolate. One worker can harvest about 1500 pods per day—enough to produce nearly 120 pounds of bittersweet chocolate. It will take another worker a full day to open those pods for fermentation.

FERMENTATION

Fermentation is the first critical process to develop the beans' natural flavors. The principal effect of fermentation is to eliminate or drastically reduce astringency and to develop the full cacao flavor. The fermentation process transforms the flavor to what we associate with cocoa and chocolate. Without the fermentation process there will not be any chocolate flavor. The fermentation process takes anywhere from two to eight days depending on the type of cacao variety. Chocolate made from unfermented cocoa beans does not have the body and richness as chocolate made from fermented cocoa beans. Chocolate does continue to be made from unfermented beans in parts of Mexico and Central America for use in traditional dishes.

Cocoa beans have a white, mucilage-like coating around each bean. Cocoa sweatings, the pale yellowish liquid that drains off during cocoa fermentation, is the breakdown product of the mucilage surrounding the fresh cocoa bean, and constitutes about 10% of the weight of the cocoa fruit. Although usually discarded the liquid has been shown to be a suitable medium for the production of wines, alcohol, marmalade, jam and syrup. I

Anaerobic Phase

The first 48 hours is the anaerobic phase during which the yeast and the sugar in the pulp surrounding the beans are transformed into alcohol and carbon dioxide. Insects, such as the Drosophila melanogaster or vinegar-fly, are probably responsible for the transfer of micro-organisms to the beans.

Aerobic Phase

At the end of the 48 hours, the aerobic phase commences, as the beans are turned, aeration allows strong growth of Acetobacter (aerobic bacteria), which transforms alcohol to acetic acid. At this stage the temperatures begin to rise up to 50 C.

The bud (or germ) within the cacao bean dies from the heat, alcohol, and acetic acid. When the bud dies, important chemical changes begin as enzymes within the bean itself are released. These are important for the development of the chocolate flavor. -

In order to facilitate the fermentation process the top layer of the beans are covered with banana leaves. The plastic, covered by the jute bags helps to further conserve the heat, and induce the "sweating" process that the beans undergo. Banana leaves are used since the bottom part of the banana leaf contains natural yeast and microorganisms, which helps to strengthen the natural fermentation process of the beans

-- See excellent summary table here for fermentation process (reference: from cocoa tree to bean,

DRYING

When the fermentation is terminated the cacao beans are sun-dried. In small plantations the fermented beans are spread by hand, and later turned over by hand or foot. In Central America the beans are dried on wooden floors which can be covered by a sliding roof if it starts to rain. On larger plantations electric dryers are used.The drying process takes 1-2 weeks, and during that period the color changes from reddish brown to dark brown.

MANUFACTURING PROCESS----

Although the processing of cocoa beans has already begun, since the farmer fermented and dried them, before they can enter a manufacturing facility, they must be inspected and approved as part of a stringent quality control process.

SORTED CLEANED AND ROASTED

It is only after roasting that the distinctive, chocolate aroma becomes pronounced. Prior to this stage, a person with a developed sense of smell will be able to detect a slight chocolate scent but following roasting the aroma becomes nearly intoxicating — beautiful, rich and laden with the heady, euphoric scent of pure chocolate.

Roasting accomplishes several things:

1-- it will kill any organisms that are present on the bean. This is important especially since during the fermentation process numerous bacteria are present.

2--It helps separate the outer husk from the inner bean and makes cracking and winnowing easier.

3--Allows for chemical reactions to occur which is is integral to good flavored chocolate.

Roasting, like cocoa seed fermentation , is a crucial stage in establishing the final flavor of the chocolate. The ultimate quality of the chocolate depends as much on the correct choice of roasting conditions as it does on the characteristics of the raw cocoa beans. There are several roasting processes:

Pre-roasting

The cocoa beans are quickly heated with hot air or infra-red radiant heaters to separate the shells from the 'nibs', or bean meat. The beans are roasted at temperatures between 100°C (212°F) and 150°C (300°F) for between twenty and forty minutes.

Direct roasting (without pre-roasting)

The beans, still in their shells, are roasted and then shelled all at once. This older and more traditional method allows the flavor to develop properly. As a guide, this type of roasting is carried out at between 150°C and 160°C (300°F-320°F) for forty to fifty minutes.

Both techniques are still used today and each has its advocates. The use of pre-roasting is more productive, but some varieties of beans, when shelled, can be damaged by a too-violent change in temperature during roasting.

Why Roast?

Roasting dries and browns the cocoa beans and develops their flavor. This is the first important stage in the manufacturer's 'customization' of the product. Earlier, fermentation has produced the flavor precursors: reducing sugars, glucose and fructose, and amino-acids. Even though roasting can only reinforce the results of good fermentation, it can only also spoil very high-quality beans if not done correctly.

How to Roast Cocoa Beans at Home

With all of the methods, the basic technique is the same. Subject the cocoa beans to a high temperature initially, slowly reduce the temperature and stop the roast when the beans are "cracking", but before they start to burn.

The initial high heat lets the beans gain some thermal momentum and allows for a good separation of the husk and nibs as the beans expand. You lower the ambient temperature so as not to burn the outside of the bean, but let the interior continue to roast. Finally, the cocoa beans will start to pop and crack as water vapor is explosively released. This happens when the cocoa bean temperature is around 300 F. This is your sign you are just about done roasting. Experience and smell (you don't want any burned smell) are the key indicators when the beans are roasted. Once the cocoa beans are roasted and cooled, try separating the husk from one. If it comes off easily, you did well and the beans are fully roasted. Likewise, taste some. They should have a nice cocoa flavor, with no raw or burned flavors.

WINNOWING

After roasting, the beans are "winnowed" to remove the shells from around the bean, leaving only the roasted cocoa nib, which is the key ingredient for making chocolate. Machines crack the beans open. Then powerful fans blow over the beans carrying the lighter shells away, leaving behind pure cocoa pieces called nibs.

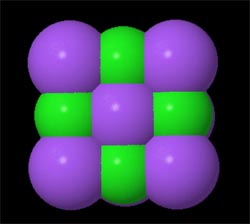

GRINDING OF NIB

After roasting and winnowing, the cocoa nibs are ground into a paste called chocolate liquor (a.k.a cocoa mass). Chocolate liquor contains both cocoa solids and cocoa butter in roughly equal proportion. Cocoa liquor is not alcoholic; it is so named because it flows out in liquid form. Cocoa liquor is a deep, dark brown color, extremely aromatic with a rich, bitter taste. Cocoa liquor can rightfully be thought of as the "essence of the bean". Cocoa liquor contains over 300 chemical compounds that give chocolate its addictive, aphrodisiac and euphoria-inducing attributes. The liquor imparts the distinctive flavor and aroma to finished chocolate.

The cocoa mass can be heavily pressed until the cocoa butter is squeezed out, and it is separated into cocoa powder and cocoa ----This is made up of rich cocoa butter (55-60%) with fine cocoa particles suspended in it. Chocolate liquor can either be used directly in the production of chocolate bars or further processed to separate the fat, known as cocoa butter, from the cocoa solid, leaving cocoa presscake.

Cocoa butter imparts no flavor or aroma at all to the finished chocolate. It is a fat and imparts the wonderful smoothness — what is termed "mouth feel" to chocolate. Cocoa butter has a very low melting point (it melts at body temperature) and is expressed as a clear liquid that floats to the top of a vessel while the dense cocoa liquor settles to the bottom much as oil and vinegar separate with a clear line of demarcation between the two ingredients.

CONCHING

The penultimate process is called conching. Conching further refines the chocolate mass with continued grinding. It is at this stage in manufacturing where the maker adds more ingredients such as sugar, milk powder (only if making milk chocolate) and other ingredients and flavorings. Each chocolate maker has his or her own preferred time for conching. It can be as little as a few hours or as long as a few days. The process affects the size of the particles in the chocolate when finished, and the chemical structure of the chocolate, which affects the flavor of the product. Chocolate prior to conching has an uneven and gritty texture. The conching process produces cocoa and sugar particles smaller than the tongue can detect, hence the smooth feel in the mouth.

BLENDING

Chocolate liquor is blended with cocoa butter in various quantities to make different types of chocolate. The basic blends of ingredients for the various types of chocolate (in order of highest quantity of cocoa liquor first), are:

Dark chocolate: sugar, cocoa butter, cocoa liquor, and (sometimes) vanilla

Milk chocolate: sugar, cocoa butter, cocoa liquor, milk or milk powder, and vanilla

White chocolate: sugar, cocoa butter, milk or milk powder, and vanilla

TEMPERING

The final process in making chocolate is called tempering. Uncontrolled crystallization of cocoa butter typically results in crystals of varying size, some or all large enough to be clearly seen with the naked eye. This causes the surface of the chocolate to appear mottled and matte, and causes the chocolate to crumble rather than snap when broken. The uniform sheen and crisp bite of properly processed chocolate are the result of consistently small cocoa butter crystals produced by the tempering process.

The tempering process--

Generally, the chocolate is first heated to 50 °C to melt all six forms of crystals.

Next, the chocolate is cooled to about 27 °C, for a few minutes which will allow crystal types IV and V to form. At this temperature, the chocolate is agitated to create many small crystal "seeds" which will serve as nuclei to create small crystals in the chocolate.

The chocolate is then heated to about 31 °C to eliminate any type IV crystals, leaving just type V. After this point, any excessive heating of the chocolate will destroy the temper and this process will have to be repeated.

Other methods of chocolate tempering may also be used. The most common variant is introducing already tempered, solid "seed" chocolate. The temper of chocolate can be measured with a chocolate temper meter to ensure accuracy and consistency. A sample cup is filled with the chocolate and placed in the unit which then displays or prints the results.

Chocolate tempering machines (or temperers) with computer controls can be used for producing consistently tempered chocolate, particularly for large volume applications.

READINGS AND REFERENCES

From Cacao Tree to bean: The beginning of fermentation

How does fermentation work on the cocoa bean

How to Make Chocolate-- Omanhene

How Chocolate is Made -- Ecole Chocolat

ICE Bean to Bar Chocolate in 10 Steps

Chocolate – The Noblest Polymorphism II

The Food Lab -- The Best Way to Temper Chocolate

Guittard -- from bean to bar -- The Art of Chocolate Making

|

Science of Chocolate

What are the health benefits of Chocolate?

What are the drugs in Chocolate?

Research on Chocolate and Cocoa

Who makes the best Chocolate in the World?

Science of Cooking

See also: